Ikukhazikitsidwa kwa Compound Fertilizer Production Line

Compound Feteleza ndi fetereza yomwe imakhala ndi michere iwiri kapena itatu ya N, P;K. Feteleza wamagulu amapezeka mu ufa kapena granular.Nthawi zambiri amagwiritsidwa ntchito ngati feteleza ndipo amathanso kugwiritsidwa ntchito ngati manyowa oyambira komanso manyowa ambewu.Feteleza wamagulu ali ndi zigawo zogwira mtima kwambiri, choncho amasungunuka mosavuta m'madzi, amawola mofulumira, ndipo amatengedwa mosavuta ndi mizu, choncho amatchedwa "feteleza wofulumira".Ntchito yake ndikukwaniritsa zofunikira zonse ndikulinganiza zakudya zosiyanasiyana zomwe mbewu zimafunikira mumikhalidwe yosiyanasiyana.

Izi feteleza kupanga mzere makamaka ntchito granulate pawiri feteleza granules ntchito zipangizo NPK, GSSP, SSP, granulated potaziyamu sulphate, sulfuric acid, ammonium nitrate, ndi ena.Zida zopangira feteleza zili ndi ubwino wake wokhazikika, kuchepa kwachangu, kukonza pang'ono komanso mtengo wotsika.

Mzere wonse wopanga uli ndi zida zapamwamba komanso zogwira mtima, zomwe zimatha kutulutsa matani 50,000 a feteleza pawiri pachaka.Malinga ndi zofunikira zenizeni zopangira, timakonzekera ndikupanga mizere yopangira feteleza yokhala ndi mphamvu zosiyanasiyana zapachaka za matani 10,000 ~ 300,000.Zida zonse ndizophatikiza, zomveka, zasayansi, zokhazikika, zopulumutsa mphamvu, zotsika mtengo zokonza, zosavuta kugwiritsa ntchito, ndiye chisankho chabwino kwambiri kwa opanga feteleza apawiri.

Njira yopangira feteleza wapakatikati

Njira yopangira feteleza pawiri imatha kugawidwa kukhala: zopangira zopangira, kusakaniza, kuphwanya, granulating, kuwunika koyambirira, kuyanika kwa granule ndi kuziziritsa, kuwunika kwachiwiri, ❖ kuyanika granule ndi ma CD ambiri.

1. Kuphatikizika kwa zinthu zopangira: molingana ndi kufunikira kwa msika ndi zotsatira za kutsimikizika kwa nthaka, zopangira monga urea, ammonium nitrate, ammonium chloride, ammonium sulphate, ammonium phosphate (monoammonium phosphate, diammonium phosphate, heavy calcium, general calcium) ndi potaziyamu chloride ( potaziyamu sulphate) iyenera kugawidwa mu gawo linalake.Zowonjezera ndi kufufuza zinthu zimayesedwa ndi sikelo ya lamba ndikufanana ndi gawo linalake.Malinga ndi chiŵerengero cha formula, zipangizo zonse zimasakanizidwa mofanana ndi chosakanizira.Njirayi imatchedwa premix.Imawonetsetsa kupangidwa kolondola ndikupangitsa kuti ikhale yogwira ntchito komanso yosalekeza.

2. Kusakaniza: Sakanizani bwino zopangira zokonzekera ndikuzisakaniza mofanana, zomwe zimayala maziko a feteleza wabwino komanso wapamwamba kwambiri wa granular.Chosakaniza chopingasa kapena chosakaniza cha disc chingagwiritsidwe ntchito ngakhale kusakaniza.

3. Kuphwanya: Kuphwanya caking mu zipangizo ndi zofunika kuti wotsatira granulation processing.Chain crusher imagwiritsidwa ntchito kwambiri.

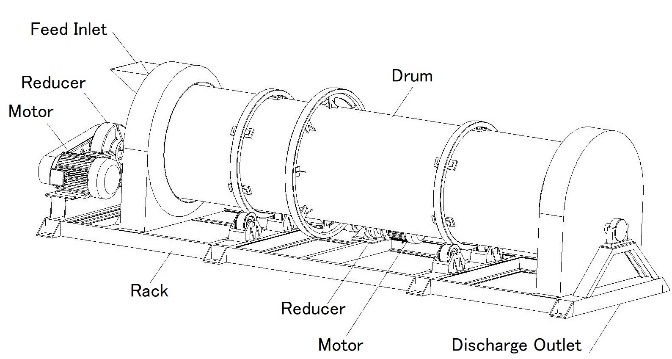

4. Granulating: Zosakaniza zosakanikirana ndi zophwanyika zimatumizidwa ku granulator kudzera pa conveyor lamba kwa granulating, yomwe ndi gawo lalikulu la mzere wonse wopanga.Kusankha granulator ndikofunikira kwambiri, tili ndi granulator ya disc, rotary ng'oma granulator, roller extrusion granulator kapena pawiri feteleza granulator kuti tisankhe.

5. Kuyang'ana koyamba: Yang'anani koyambirira kwa ma granules, ndipo bwezerani omwe sanayenere kuphwanyidwa kuti apangidwenso.Kawirikawiri, makina owonetsera rotary amagwiritsidwa ntchito.

6. Kuyanika: Ma granules oyenerera pambuyo poyang'ana koyamba amanyamulidwa ndi chotengera lamba kupita ku chowumitsa chozungulira kuti awunike kuchepetsa chinyezi cha ma granules omalizidwa.Pambuyo kuyanika, chinyezi cha granules chidzatsika kuchokera 20% -30% mpaka 2% -5%.

7. Kuzizira kwa ma granules: Pambuyo poyanika, ma granules amatumizidwa ku chozizira kuti chiziziritsa, chomwe chimalumikizidwa ndi chowumitsira ndi lamba.Kuziziritsa kumatha kuchotsa fumbi, kuwongolera kuzizira bwino komanso kugwiritsa ntchito kutentha, ndikuchotsanso chinyezi mu feteleza.

8. Kuwunika kwachiwiri: Pambuyo pa kuziziritsa, ma granules onse osayenerera amafufuzidwa kudzera mu makina osindikizira ozungulira ndikunyamulidwa ndi chonyamulira lamba kupita ku chosakanizira ndikusakaniza ndi zipangizo zina zopangiranso.Zotsirizidwazo zidzatumizidwa ku makina opaka feteleza apawiri.

9. Kupaka: Kumagwiritsidwa ntchito makamaka kuphimba pamwamba pa quasi-granules ndi filimu yotetezera yunifolomu kuti iwonjezere bwino nthawi yosungiramo ndikupangitsa kuti granules ikhale yosalala.Pambuyo ❖ kuyanika, apa bwerani otsiriza ndondomeko - ma CD.

10. Packaging system: Makina opangira ma CD okhazikika amatengedwa mwanjira iyi.Makinawa amapangidwa ndi makina oyezera ndi kulongedza okha, makina otumizira, makina osindikizira ndi zina zotero.Hopper imathanso kukhazikitsidwa malinga ndi zomwe makasitomala amafuna.Kuyika kwachulukidwe kwazinthu zambiri monga feteleza wachilengedwe ndi feteleza wapawiri kwagwiritsidwa ntchito kwambiri m'mafakitale ndi minda yosiyanasiyana.

Tekinoloje ndi Zochita za mzere wopangira feteleza wambiri:

Rotary ng'oma granulator makamaka ntchito yopanga mkulu-ndende pawiri feteleza luso, chimbale sanali nthunzi granulator angagwiritsidwe ntchito kupanga mkulu, sing'anga ndi otsika ndende ya pawiri feteleza luso, kuphatikizapo odana caking luso, mkulu nayitrogeni. ukadaulo wopangira feteleza wambiri ndi zina zotero.Njira yathu yopangira feteleza ili ndi izi:

1. Kugwiritsa ntchito kwambiri kwa zopangira: feteleza wophatikizika amatha kupangidwa motengera momwe amapangira komanso kuchuluka kwake, komanso ndi oyenera kupanga feteleza wa organic ndi inorganic pawiri.

2. Kuchuluka kwa mapangidwe a pellets ndi kupulumuka kwa mabakiteriya achilengedwe: teknoloji yatsopano ikhoza kupangitsa kuti chiwerengero cha pellet chifike pa 90% ~ 95%, ndi teknoloji yotsika kwambiri komanso yowumitsa mpweya wambiri ingapangitse kupulumuka kwa tizilombo toyambitsa matenda. kufika 90%.Chomalizidwacho chimakhala chabwino m'mawonekedwe komanso kukula kwake, 90% yake ndi ma granules okhala ndi kukula kwa 2 ~ 4mm.

3. Flexible ndondomeko otaya: The ndondomeko otaya pawiri mzere kupanga fetereza akhoza kusintha malinga ndi zipangizo zenizeni, chilinganizo ndi malo, ndi makonda ndondomeko otaya angathenso kupangidwa malinga ndi zosowa zenizeni.

4. Chiŵerengero chokhazikika cha michere ya zinthu zomalizidwa: kupyolera mu metering yokha ya zosakaniza, metering yolondola ya mitundu yonse ya zinthu zolimba, zamadzimadzi ndi zina zopangira, pafupifupi kusunga bata ndi mphamvu ya zakudya zonse mu ndondomeko yonse.

COmpound Fertilizer Production LineMapulogalamu

1.Sulfur yokutidwa urea kupanga ndondomeko.

2.Zosiyana zamtundu wa feteleza wa organic ndi organic.

3.Acid pawiri fetereza granulation ndondomeko.

4.Ufa mafakitale zinyalala inorganic fetereza ndondomeko.

5.Large tinthu urea kupanga ndondomeko.

6.Njira yopangira fetereza ya Seedling Substrate.

Nthawi yotumiza: Sep-27-2020